Vertical Carousel Module (VCM)

The new Kardex Megamat is an automated carousel which rotates vertically around a track to bring stored inventory to an operator.

Vertical carousels work in line with the goods-to-person principle. They are perfectly suited for goods with a high picking frequency and for similarly sized inventory.

Warehouse requirements

- Fewer picking errors

- More storage capacity in a smaller footprint

- High flexibility and modularity

- Faster and reliable order fulfillment

- Modern design and future-orientated technology

- Reliable intralogistics solutions

Benefits at a glance

-

Fast access to all stored goods

-

High picking productivity and increased picking accuracy

-

Maximum use of space in a minimal footprint

-

The modular and scalable system allows to start with basic functionalities and expand them afterwards

-

Extensive safety features and ergonomic design

-

Intuitive user interfaces and operating concept

Fast access to all stored goods

High picking productivity and increased picking accuracy

Maximum use of space in a minimal footprint

The modular and scalable system allows to start with basic functionalities and expand them afterwards

Extensive safety features and ergonomic design

Intuitive user interfaces and operating concept

How does the Vertical Carousel Module work?

Kardex Megamat models

Tab Navigation

Kardex Megamat 180

Efficient storage and fast retrieval of lightweight loads

The Kardex Megamat 180 is best suited for the storage and picking of small parts. For example, it’s an excellent choice for the hotel industry, medical sectors, vehicle manufacturing, mechanical engineering and the electronics industry.

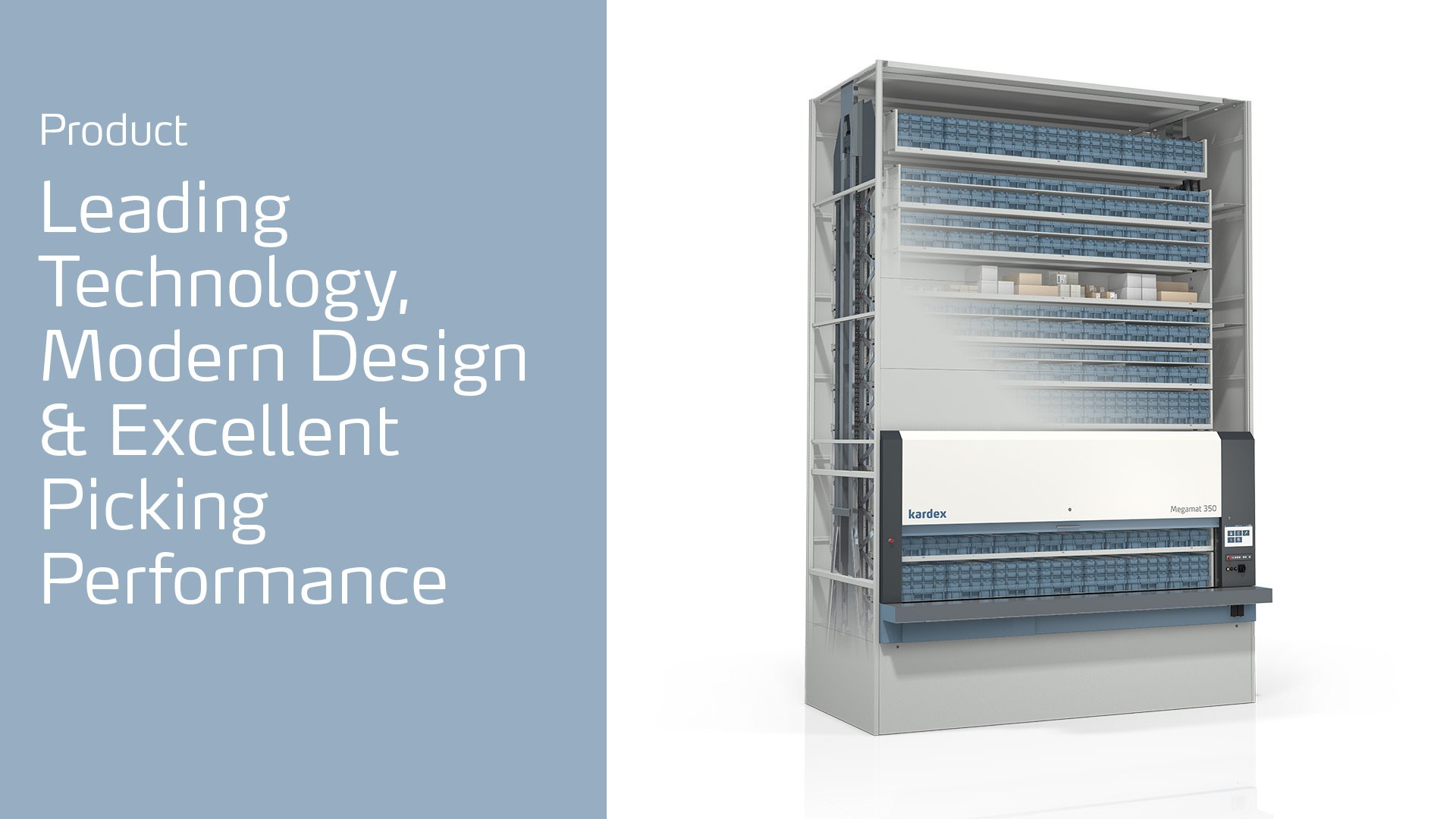

Kardex Megamat 350

Ideal for medium-sized loads

The Kardex Megamat 350 works well in a variety of different areas. For instance, it integrates into the production process in several ways – either as an interim storage solution for semi-finished products or as a buffer storage in between production steps.

Kardex Megamat 650

For heavy loads of up to 650 kg per carrier

The Kardex Megamat 650 works well in a variety of different areas. For instance, it integrates into the production process in several ways – either as an interim storage solution for semi-finished products or as a storage buffer during drying phases.

System features

The Kardex Megamat is equipped with the following technical features:

In the event of a power outage, the emergency hand crank provides access to stored products at all times.

The new chain tensioner significantly reduces the susceptibility of the load chain to wear and tear. The result is a reliable and long-lasting storage system.

The lockable sliding door moves smoothly, either automatically or manually. This guarantees it’s easy to use and ensures employees continue working without interruptions.

The innovative clip system allows a simple, fast and safe panel assembly. The increased system stability guarantees maximum protection both for stored goods and on-site warehouse workers.

Options for individual requirements

- New Kardex VCM Box

- ESD design

- Divided frame side panels

- Several access openings

- Position Indicator or Display LED-Navigator

- User management

Carriers

The Kardex Megamat carriers provide efficient, orderly storage. Optimized for different processes, they can be adapted to meet your business needs.

The maximum storage space per carrier is up to 16 square meters. Depending on the size of the unit, the maximum load capacity is 180, 350, or 650 kilograms per carrier. The carrier depth, width, and height are configured to your requirements.

Depending on the application, the carriers can be subdivided using intermediate shelves. You can use a combination of drawers, and dividers as required.

- Open carrier to provide various storage options

- Carrier with drawers, separator sets, and intermediate shelves for combining various inventory

- Carrier with partitions for easy sorting of stored goods

- Carrier with self-supported intermediate shelf for storage of large, flat parts

Every Kardex Megamat is configured to meet your needs

Technical data of the Vertical Carousel Module

| Kardex Megamat 180 | Kardex Megamat 350 | Kardex Megamat 650 | |

|---|---|---|---|

| Width | 1,875 to 3,875 mm | 1,875 to 4,275 mm | 1,975 to 4,275 mm |

| Height | 2,210 to 7,510 mm | 2,360 to 10,010 mm | 2,360 to 10,010 mm |

| Depth | 1,251 mm, 1,441 mm, and 1,631 mm * | 1,271 mm, 1,471 mm, and 1,671 mm * | 1,311 mm, 1,511 mm, and 1,711 mm * |

| Load per carrier | Max. 180 kg | Max. 350 kg | Max. 650 kg |

| Unit load (incl. carrier) | Max. 6,000 kg | Max. 12,500 kg | Max. 19,000 kg |

Product add-ons

The new Kardex VCM Box

Modular storage boxes with a divider system.

The box is perfectly adapted for the Vertical Carousel Module (VCM). Storage boxes can be adapted at any time by using cross and longitudinal dividers. The height of the Kardex VCM Box extends by using clip-on frames. The cross and longitudinal dividers are also available in different heights.

Power Pick Software Solutions

Kardex Power Pick System

Kardex Power Pick System optimizes storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies.

Power Pick Onboard

The Onboard inventory management software combined with automated storage and retrieval systems (ASRS), streamlines and accelerates warehouse processes.

Controlled environment

Inventory sometimes requires special storage conditions. Depending on your individual needs, Kardex supplies four optional environment solutions. Kardex can integrate these into your storage and retrieval system and as a result, your sensitive goods are always protected.